Thanks to Aniket Vaishya of Shailesh J. Mehta School of Management,IIT Bombay.

A) Introduction:

Somewhere in the English County of Essex, a farm has connected its cows to the internet so that the farmer can be easily intimated about any situation that requires his attention. This Cow Tracking Project makes use of the data collected from radio positioned tags to observe and control the herd’s behavior – that is, if the behavior of an animal doesn’t seem to be as expected, the farmer can locate the animal and fix up any issue it might be suffering from. Sounds disruptive, doesn’t it? How about fitting vehicles across a whole country with a safety device, that, in the event of a collision or an accident, sends its location and impact information to an emergency service center? This is precisely what the European Union is mandating all new cars in the continent to be equipped with – the eCall system.

The idea behind each of these applications is fundamentally the same – real time generation and sharing of information. It’s a connected world today and the pace at which smart devices are becoming ubiquitous, no wonder a technology that binds together the connectivity and “smartness” of these devices has caught the imagination of one and all. And rightly so, it is being tipped as the next revolution of the information age – a revolution which personifies things by imparting them an ability to “talk”. This next big thing, which very well might dwarf the transformations brought about by the internet and mobile connectivity over the past two decades, is called the “Internet of Things”.

While a multitude of applications can be thought of for this budding technology ranging in fields from science to defense, the role it would eventually play in shaping businesses worldwide is probably the one where it would hold paramount value. The dynamics of the current business environment have led to the rise of a new type of asset – information. How well an organization manages and makes use of this asset, more often than not, distinguishes a leading organization from the also-rans. And precisely for this reason, internet of things (IoT) might have a say in businesses, small or large, in one of their most information intensive functions – Supply Chain.

B) Supply Chain & Internet of Things:

A supply chain, basically, is a co-ordination between two flows – physical (product) and information. Downstream physical flows broadly include procurement of raw materials, their transformation to finished goods, their storage and subsequent delivery to the customers, while upstream physical flows include reverse logistics of damaged and returned goods for disposal or reselling. On the other hand, both stream information flows primarily consist of information accompanying the respective flow of product. These include order confirmation, tracking information, shipping notices and billing information in the downstream part, while sales and usage information and information related to product returns in the upstream part.

Most issues of inefficiencies and under-utilization of system capability arise due to a gap that exists between these two flows as the information flow cannot reflect the wave of material flow, in real time. For example, the exact location and status of an in-transit inventory can never be known accurately to the supply chain manager unless the inventory is at one of the nodes in the supply chain. Consequently, there is no real time visibility of the supply chain execution as such. IoT, an extension of the internet and one which enables communication between objects (things), has the capability to plug this gap. By establishing connections and communications between objects, it can allow real-time collection of information from them, while through the ubiquitous computing environment of the internet; it can allow real-time processing of that information.

C) Internet of Things: Implementation

Before we dive into the details of IoT’s impact on supply chains, let us consider what enables this technology and how it can be put to use.

Radio Frequency Identification (RFID) Technology

The driver of IoT’s implementation for supply chain management is the RFID technology which is essentially a transmitter-receiver system. Basically, it consists of radio “tags” – active or passive (depending upon the existence of an on-board battery) – which can be so small that they can be embedded even inside ants. These tags embedded inside objects are then triggered by “interrogators” or “readers” by sending a signal to them, on receipt of which the tags reply with the information they contain. Tags can also be programmed to update the data they contain.

The main advantage of this system comes from its use of electromagnetic radio waves in transfer of data. This allows the tags to be embedded inside objects rather than on them and send signals to distances up to 100 meters depending upon the configuration of tags and readers used. What this means from a supply chain perspective is that, for tracking/counting/inspecting of inventory in a warehouse or a factory, the goods need not be taken out from their packages to bring them in the range of a receiver – a drastic improvement over the traditional bar-code system, where the bar-code on the object needed to be positioned in the line of sight of the reader in order to extract information from it. The fact that multiple tags can be interrogated by the reader simultaneously adds another layer of advantage over the uni-processor bar code system. Finally, the data hence obtained by the readers in the RFID system, can be made available to the different agents in the supply chain in real time with the help of attached software and broadcasting systems (see figure below).

RFID Applications:

This simple RFID-enabled IoT has found ample usage in supply chains across sectors and industries. In 2004, aviation industry major Boeing made use of this technology to control the maintenance and inventory costs of its Dreamliner 787 project. To be precise, the company saved a total of $29000 in labor, courtesy efficient integration of IoT in existing operations.

Another interesting application of this technology is the use of “smart shelves” – retail shelves that have RFID readers built in – to avoid stock-outs in retail business. Metro AG, a German supermarket chain, experimented with item-level RFID in one of their stores known as the Metro Future Store. Here, the smart shelves on which the RFID tagged products are displayed and send a notification to the backroom as soon as the quantity of products on the shelf decreases to a certain threshold. This has helped them reduce shelf stock-out costs which in 30% of cases was a result of inefficient replenishment from the backroom.

IoT: Architecture and Components

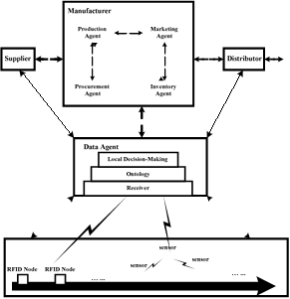

Along with RFID, true value to the supply chain will be achieved when suitable changes are made in the traditional supply chain architecture in order to incorporate the processes and implications of IoT. IoT based systems collect data automatically as opposed to manual collection in traditional SCM systems. Hence, in order to take advantage of the humongous data collected from various sensors, efficient data processing techniques will have to be developed along with a phased replacement of the centralized SCM architecture by a more distributed one (see diagram below)

IoT introduces the conc ept of “smart” items – data agents – that are intelligently deployed for data collection, filtering and conversion to process business logic. As is evident from the figure, the RFID and sensors deployed in the system timely capture information and send it to the data agents which process it and make local decisions to enhance the supply chain’s response. Ultimately, by allowing the information flow from multiple agents, this arrangement builds the capabilities for a collaborative SCM among the stakeholders from suppliers to distributors realizing the true value of the activity.

ept of “smart” items – data agents – that are intelligently deployed for data collection, filtering and conversion to process business logic. As is evident from the figure, the RFID and sensors deployed in the system timely capture information and send it to the data agents which process it and make local decisions to enhance the supply chain’s response. Ultimately, by allowing the information flow from multiple agents, this arrangement builds the capabilities for a collaborative SCM among the stakeholders from suppliers to distributors realizing the true value of the activity.

D) Internet of Things: Impact

Undoubtedly, the most important impact that implementing the pervasive Internet of Things would bring about is the enhanced visibility of the supply chain.

Meeting this critical need for achieving an efficient flow of material and information, following is a gist of how this perceived advantage and IoT as a whole will impact the core activities of the supply chain:

- Sourcing: Along with supporting the existing internet-enabled processes like e-collaboration and e-procurement, IoT thanks to its ubiquitous information access, can capture in real time the state of the material to be purchased thereby helping the organization to meet its desired criteria for the sourced inputs.

- Manufacturing: Use of sensor enabled devices in the production environment help the controller to have a real time visibility over running processes thereby, minimizing the chances of risky conditions escaping unattended. RFID tagged items also provide accurate and timely information on the state of the product being developed helping considerably in monitoring and improving the quality of the end-product.

- Storing: As explained above, initiatives like smart shelves are leading to a better storage of inventory in back rooms as well as in retail spaces. Also, IoT enabled visual management of inventory allows dynamic inventory information to be collected automatically over the internet further decreasing the gap between the physical and the information flows.

- Delivering: With organizations scrambling to distribute products into newer distant markets, substantial part of a product’s lifetime is spent in transit. IoT can be used to obtain the status and location information of the goods in transportation thereby Infusing more transparency, decision making capability and safety for the products.

What the experts say?

Academia and industry alike have hailed the positive impacts that IoT implementations will have in the supply chain function.

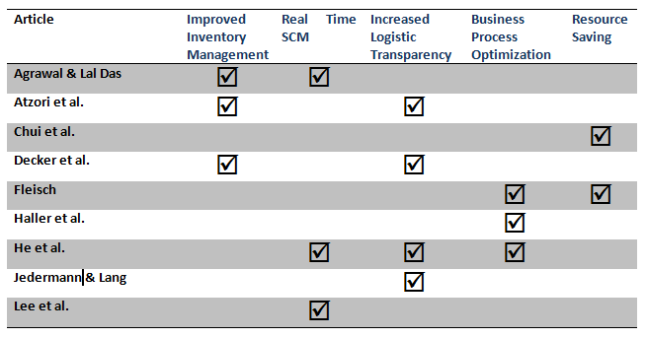

The following matrix shows how various research articles have suggested different kind of advantages the new technological is poised to bring in:

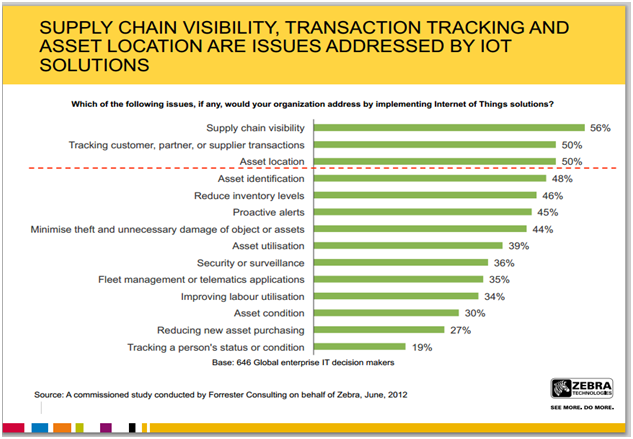

And a study conducted by Forrester Consulting reveals what effects the industry expects the IoT to bring in:

E) Conclusion

The technology that enables Internet of Things is still in a developing stage and a ubiquitous deployment still remains a work in progress for primarily the want of a global standard for seamless integration. Along with it, business, policy and technical challenges must be addressed before its widespread application. Industry groups and regulators will have to play their part concerning the data privacy and security aspects of IoT, particularly the ones that touch upon sensitive consumer information. In addition to it, legal frameworks will have to be established by governments and risk analysts pertaining to the ill usage of these enhanced automation systems. On the technology side also, the costs of sensors and actuators must drop to levels that can spark widespread usage, and data aggregating and analyzing software systems be evolved to enable human comprehension of the vast amount of data.

Though these challenges remain, yet, there is no denial of the capabilities that this technological advancement brings along. IoT builds a bridge between the physical and the virtual world, and its adoption has the potential to enhance operational processes as well as reduce costs and risks thanks to its traceability, transparency, scalability and flexibility – system qualities that are of paramount importance in a function like supply chain.

To sum it all, supply chains across sectors and industries have traditionally been considered a function replete with costs and complexities. Though there is enough appreciation of the importance that this function holds for the organization, it is only by advancing it to the next generation can the true value for the organization be unlocked. And precisely for this evolution of SCM, all eyes have and are, set in expectation, over the power of things – the Internet of Things.